-

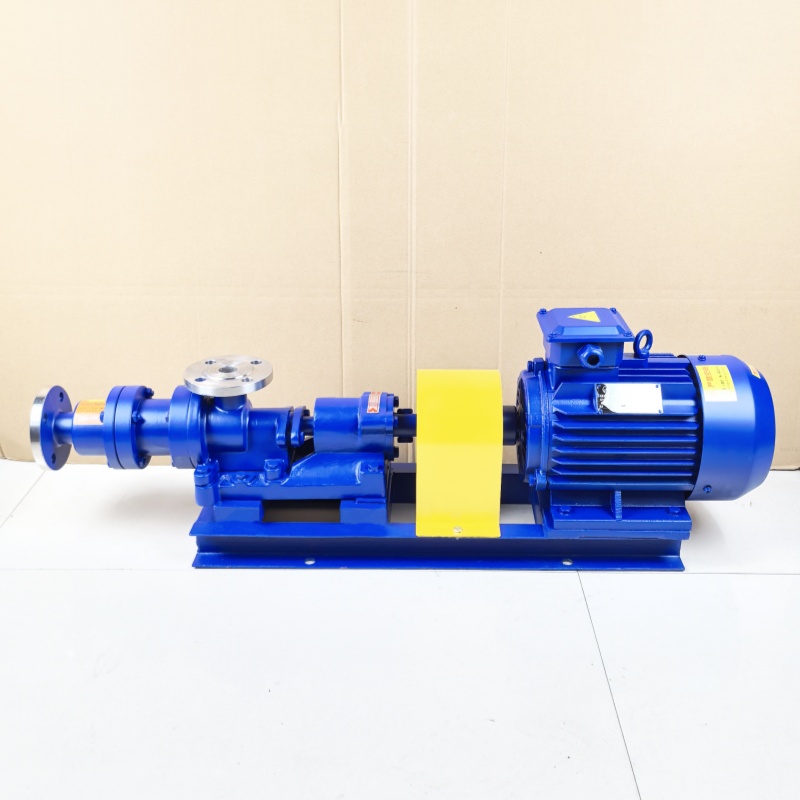

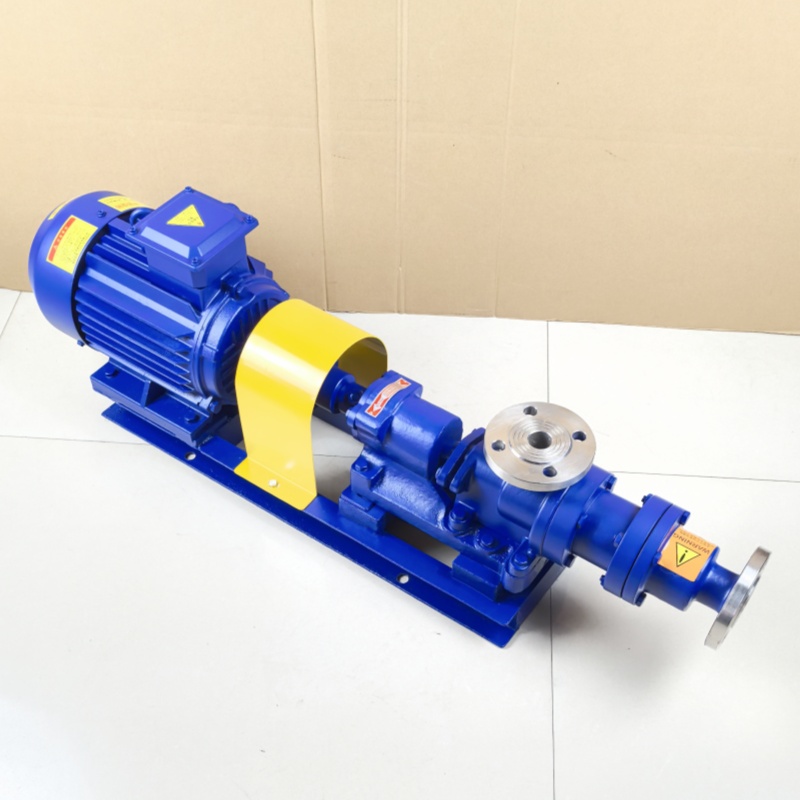

Product DescriptionCompany Info.<>

- Performance:

- Corrosion resistance

- Material:

- Stainless steel

- Driving mode:

- Electric

- Flow:

- 1.5 m3/h

- Suction caliber:

- 25 mm

- Discharge caliber:

- 25 mm

- Rotational speed:

- 960 rpm

- Lift:

- 80 m

- Operating temperature:

- 60 ℃

- Discharge pressure:

- 0.8 Mpa

- Brand:

- Shangwu Fluid

- Model:

- I-1B 1inch

product overview

The I-1B thick slurry pump generally uses a double helix bushing stator made of nitrile rubber material and an eccentric single helix screw shaft made of steel material such as 2Cr13. The flow control can be achieved by using a motor and pump shaft coupling method, or by using adjustable speed motors such as stepless speed control motors and variable frequency motors. The selection of concentrated propeller pumps should clearly specify the characteristics of medium viscosity, specific gravity, etc.

Product Features

1. It can transport high concentration, high viscosity<10000PaS and suspended slurry containing particles.

2. The conveying fluid flow is stable, without overcurrent, pulsation, stirring, or shearing of the slurry.

3. The discharge pressure is independent of the rotational speed, and high discharge pressure can be maintained even at low flow rates.

4. The flow rate is proportional to the speed, and flow regulation can be achieved through a variable speed mechanism or a speed regulating motor.

5. Strong self-priming ability, can directly suck liquid without the need for a bottom valve.

6. The pump can be reversed, and the liquid flow direction is changed by the rotation direction of the pump, which is suitable for situations where the pipeline needs to be flushed in the reverse direction.

7. Smooth operation, low vibration and noise.

8. Simple structure, easy disassembly and maintenance.

This pump is widely used in chemical, pharmaceutical, brewing, papermaking, food and other units.

Applicable scenarios

The transportation of molasses, sugar juice, bagasse, and sugar beet residue in sugar factories;

The loading and transportation of milk powder, starch, honey, coffee, milk, cream, edible oil, various vitamin liquids, maltose, tomato sauce jam, mayonnaise, ice cream, etc. from canning factories and food factories;

The feeding and batching of alcoholic beverages, spices, and fermentation liquids in breweries, as well as the transportation of grain waste residue from filter presses;

The transportation of fish liver oil, fish oil, fish floss, and fish residue in fish processing plants;

The transportation of sugar juice and fruit juice in fruit processing plants, the crushing of citrus and fruits, and the feeding of fillers in filling machines:

Filling materials and auxiliary transportation for edible oil, rice, corn starch, etc. in grain and oil processing plants;

Meat processing plants, slaughterhouse oils and fats, meat oil extraction, packaging, and transportation of waste liquids;

Pharmaceutical factory: transportation of various vitamin solutions, medicinal liquids, emulsions, transportation of suspensions, saline water, salt sludge, drug residues, etc;

Chemical industry: transportation of acids and alkalis, feeding, batching, and transportation of various suspensions, oils, adhesives, dyes, paints, adhesives, ointments, and slurries, especially for high viscosity materials or stainless steel slurry pumps with solid particles and materials that cannot be transported by conventional centrifugal pumps;

Ingredient transportation of printing ink;

The transportation of pulp and ink in paper mills;

Transportation of oil products, grease, waste liquid and sludge in petrochemical plants;

Transportation of carbide sludge from acetylene station;

In the construction industry, dysprosium is used to deliver mortar, lime milk, mortar, cement slurry, etc;

Can be used for pumping water, conveying and loading during feed processing;

Widely used in industrial and domestic wastewater and sludge treatment, wastewater usually contains many suspended solids with certain corrosiveness and viscosity, and often contains solid particles. Therefore, the use of concentrated slurry pumps for transportation is suitable;

Transportation of contaminated water, contaminated liquids, and other materials for atomic energy launch stations;

Mine wastewater and sludge discharge.

In addition, the I-1B thick slurry pump can be used in water plants in the steel industry, shipbuilding industry, ceramic industry, and leather industry.

Material form

I-1B series concentrated slurry pump: The shell casting and transmission components (main shaft, screw, and winding shaft) are made of 2Cr13 stainless steel, suitable for conveying general neutral concentrated slurry and general slightly acidic and alkaline slurry.

I-1BF series slurry pump: The transmission components and pump casing in contact with the slurry are made of stainless steel, suitable for conveying food, pharmaceutical, and corrosive slurry.

Rubber bushings are available in general wear-resistant rubber, food grade rubber, and oil resistant rubber for users to choose from.

The transmission methods include direct transmission between the motor and the pump shaft, direct transmission between the motor and the pump through a reducer, and transmission between the motor and the pump shaft through a V-belt pulley.

There are generally enclosed, explosion-proof, and electromagnetic speed regulating motors available for use with electric motors, as well as continuously variable transmissions and gear reducers for users to choose from.- Name(chinese)

- Name(English)

- Zhejiang Shangwu Fluid Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yongjia County, Wenzhou, Zhejiang, China

- Nearby port

- Wenzhou

The company mainly sells diaphragm pumps. Pneumatic diaphragm pumps can not only pump flowing liquids, but also transport some media that are difficult to flow. They have the functions of submersible pumps, self-priming pumps, impurities pumps, shielded pumps, mud pumps and many characteristics of conveying machinery. The flow is spacious and the passing performance is good, allowing passage of particles up to 10 mm. When pumping mud and impurities, there is little wear on the pump; No need for irrigation and water diversion, outlet pressure 7bar The pneumatic diaphragm pump has no rotating parts or shaft seals. The medium pumped by the diaphragm and other is completely separated from the moving parts of the pump and the workpiece media, and the medium transported will not leak out. Therefore, when pumping toxic, volatile or corrosive media, it will not cause environmental pollution and endanger personal safety; The pneumatic pump does not require oil lubrication, and even if it is idling, it will not have any effect on the pump. This is the characteristic of this pump.- Name(chinese)

- Name(English)

- Zhejiang Shangwu Fluid Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yongjia County, Wenzhou, Zhejiang, China

- Nearby port

- Wenzhou

The company mainly sells diaphragm pumps. Pneumatic diaphragm pumps can not only pump flowing liquids, but also transport some media that are difficult to flow. They have the functions of submersible pumps, self-priming pumps, impurities pumps, shielded pumps, mud pumps and many characteristics of conveying machinery. The flow is spacious and the passing performance is good, allowing passage of particles up to 10 mm. When pumping mud and impurities, there is little wear on the pump; No need for irrigation and water diversion, outlet pressure 7bar The pneumatic diaphragm pump has no rotating parts or shaft seals. The medium pumped by the diaphragm and other is completely separated from the moving parts of the pump and the workpiece media, and the medium transported will not leak out. Therefore, when pumping toxic, volatile or corrosive media, it will not cause environmental pollution and endanger personal safety; The pneumatic pump does not require oil lubrication, and even if it is idling, it will not have any effect on the pump. This is the characteristic of this pump. -

Send your message to this supplier*From:*To:

Mr. Owen

*Message:

Mr. Owen

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.